Valentin Juhasz is an electronics engineer that has worked in the building conservation sector for over a decade.

His company, Core Conservation, has recently been at the forefront of historic building dampness investigation and remediation.

His dissatisfaction with the sector’s lack of scientific understanding about the nature of moisture in brickwork has driven his recent academic work.

Now undertaking a PhD at Strathclyde University, he explains the dilemma,

“When it comes to dealing with problem dampness in pre-1930s buildings much of the conventional advice is guided by anecdotal evidence – and there is notable confusion at industry level.

Part of this issue relates to the difficulty of accurately measuring and monitoring the moisture content of masonry – and addressing this problem has become a key part of my research.”

The challenges of measuring moisture in brickwork

Valentin’s quest for a practical and accurate moisture measuring method started with the use of “air pocket” relative humidity sensors. These tiny (3mm x 3mm) microchip sensors measure air humidity values, and can be easily embedded into the brickwork.

The general assumption was that there would be a direct and identifiable correlation between the humidity values of the air pocket RH sensors – which can typically vary between 50% to 100% – and the actual (gravimetric) moisture content of the walls determined from small core samples of the bricks, which can vary between 2% (air dry) to 15% (damp) or more.

“But things are rarely so simple, and after many months of research we identified a major problem.” Valentin says.

The problem was that even when the moisture content of the walls was low, the air pocket sensors embedded in the masonry saturated quickly to near 100% RH, and became stuck at that level indefinitely.

“Multiple experiments proved this behaviour” says Valentin, “and it became clear that when the gravimetric moisture content of the bricks went above 0.5%, the RH sensors became saturated and stopped showing any moisture changes thereafter.”

This meant that in real-world conditions, where the moisture content of dry bricks rarely drops below 1-2%, air-pocket sensors are not a workable solution and can’t be trusted for under-surface moisture measurements.

Finding an approach that works

Given these results, a new and effective moisture measurement methodology had to be found, which led to Valentin exploring various soil moisture sensor solutions as a potential alternative.

“Despite the obvious textural differences between soil and masonry, there are some notable similarities” he says, “So I decided to learn all I could about soil moisture measurement technology, with a view to potentially employing it.”

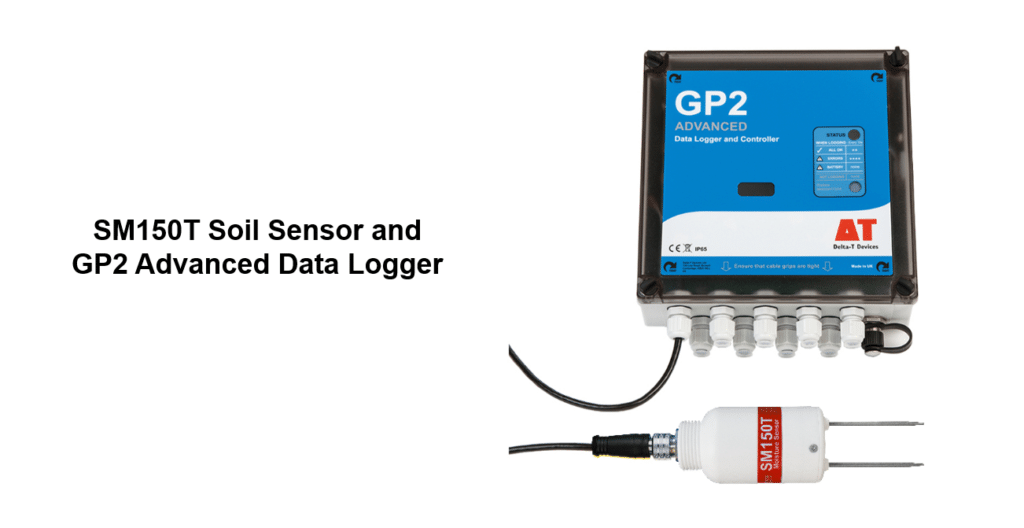

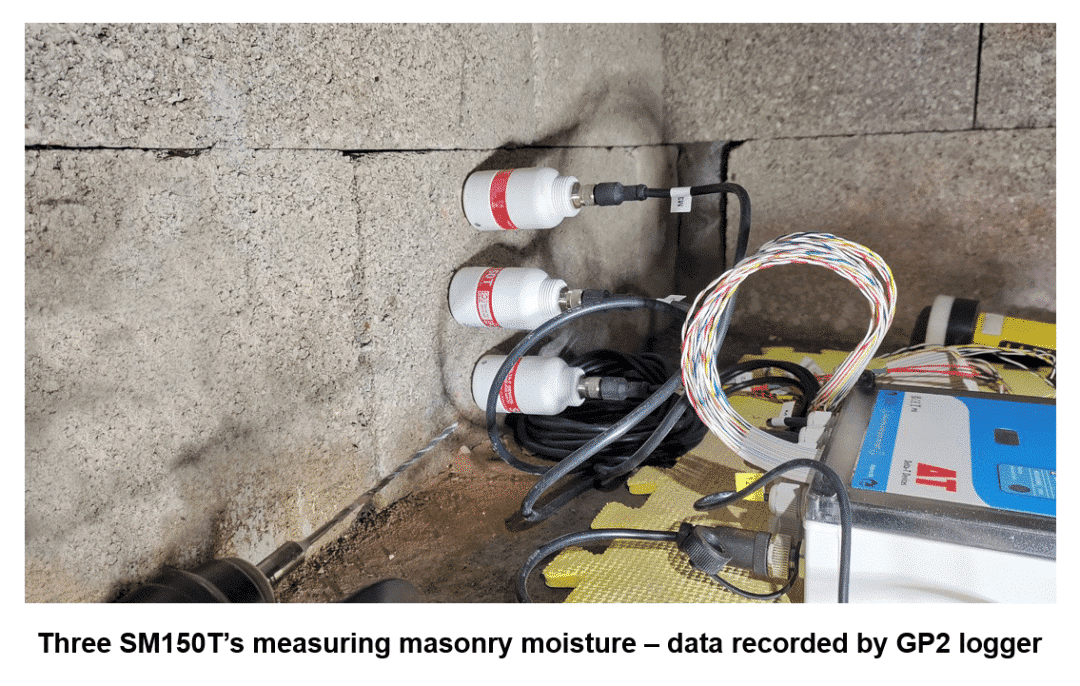

Valentin read several studies comparing multiple soil moisture measurement technologies and manufacturers, and (after extensively testing a variety of soil sensors) subsequently opted for Delta-T Devices’s SM150T Soil Sensor.

“There are several important features of the SM150T which make it the sensor of choice for this application” he says,

“Firstly, its compact size – many alternatives were large and ungainly, and hence problematic for easy effective installation into walls.

Secondly, the simple two prong design – which is much easier to install than three or four prong designs, where precisely positioned drilling of many holes is a tricky and error prone activity.

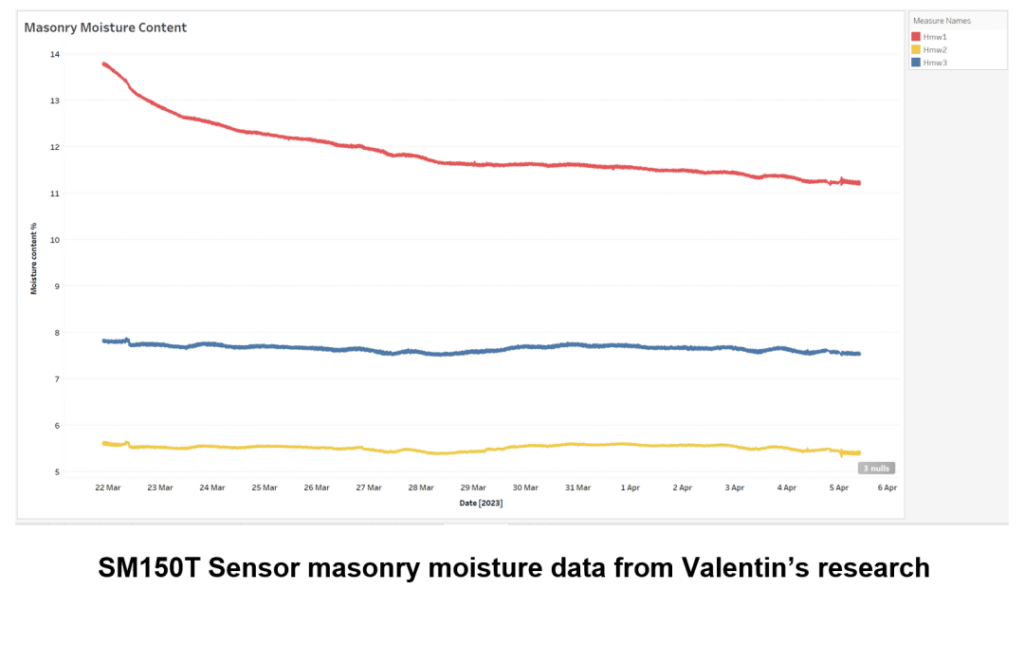

Thirdly, and most importantly, it works very well. This quickly became apparent in our initial (very low humidity environment) trials where the sensor was able to detect and track extremely small moisture changes in the brickwork as a result of changes in the surrounding vapour content. I was genuinely surprised and excited about the high sensitivity of this sensor.”

Performance in extreme conditions

Another feature that has impressed Valentin is the sensor’s ability to also function very well on the opposite end of the scale – under extreme high humidity and high salinity conditions.

“Salinity is a crucial factor in measuring moisture in historic brickwork, as evaporating moisture commonly leaves a notable build-up of salt deposits within the masonry” he says,

“The SM150T Sensor has enabled me to create compensation models (within the accompanying GP2 Data Logger) that effectively correct any anomalies that the presence of high salt levels may have on the accuracy of the moisture readings.

This was only possible because the SM150T remained functional (and gave output readings) at very high moisture and salinity levels – for example in fully saturated sand across a number of increasingly saline solutions. This enabled me to obtain the data required for creation of effective correction models.

Other soil moisture sensors I auditioned refused to operate at even moderate levels of salinity and saturation – essentially flatlining and offering no coherent measurement data to work with.”

In addition to being able to compensate high salinity affected moisture readings, Valentin has found the GP2 Data Logger to have had other benefits on his research regime, citing the robustness, weatherproofness and non-volatile memory preventing data losses as being of real value to his in-field monitoring experiments.

“It’s a great bit of fit and forget kit” he says.

Conclusions

Now that Valentin has found an effective moisture measurement solution, he is using it as a tool to further develop innovative technologies that can optimise the health of building walls (both historic and contemporary).

“I’m currently experimenting with some very exciting new approaches to manipulating the moisture levels in brickwork.” he explains,

“These non-invasive techniques are centred around affecting changes in the electromagnetic fields surrounding walls. The subsequent manipulation of wall surface charges can release low level moisture from inside the masonry, making damp walls drier.

It’s important to note that amongst many other benefits, removing dampness can improve a building’s insulating properties. A dry building is subject to less heat loss.

Given the current energy crisis, it’s an important field of research – and the Delta-T Devices equipment is proving to be a very important element in my ongoing investigations, as has the ongoing (pre and post-sale) technical support, the quality of which has been exceptional.

I would certainly encourage the science community investigating dampness in building materials, be it surface water or moisture ingress, to use this sensor technology – because it works and can be calibrated to other types of materials than soil.”

Visit Core Conservation’s website