- Overview

- Specification

- Accessories

- Product Resources

- Advanced How to Buy

Testimonials

- Ideal for demanding irrigation and fertigation applications

- Monitor soil moisture and other key growing conditions

- Directly control irrigation using-on board relays

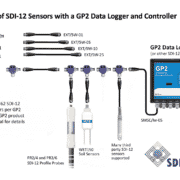

The GP2 Data Logger is a powerful monitoring and control solution for irrigation and fertigation – enabling simple or sophisticated models and multiple zone control (up to 6 relays). It has 12 differential (or 24 single ended) channels.

DeltaLINK–Cloud – online data viewing and sharing platform

Precision Irrigation

The GP2 is ideal for running precision soil moisture sensor controlled irrigation systems. These systems automatically maintain the correct levels of moisture for optimal plant growth – leading to improved yield and quality.

Find out more by clicking the relevant buttons below to download posters:

WHITE PAPER – Vapour Pressure Deficit

“Soil moisture responses to vapour pressure deficit in polytunnel-grown tomato under soil moisture triggered irrigation control”. Download it here

WHITE PAPER – Substrate Temperature Correction

“Temperature correction of substrate moisture measurements made in coir”. Download it here

The Benefits of Precision Irrigation

The GP2 can control irrigation using combined sensor inputs.

Benefits from optimising crop irrigation can include:

- Reduction in water use

- Applying less fertiliser – reduced run-off and environmental impact

- Lower energy costs for pumping water

- Compliance with national and international regulations

- Positive effect on plant growth and development – improved quality

- Saving in labour costs (e.g. less pruning)

- Increased profits

Flow Aid Project

Delta-T Devices was extensively involved in the 3 year EU funded Flow Aid Project. The aim of this project was to find new approaches to irrigation scheduling and farm management in Mediterranean countries where the supply or quality of water is low. Delta-T Devices soil moisture sensors and data loggers were used at the test sites to schedule irrigation in response to the water requirements of plants.

Script Editor Feature

The new Script Editor allows creations of step by step operations to control simple or complex processes, or recording requirements. It can also implement models, useful in areas such as disease prediction or multi-zone irrigation.

This degree of sophistication, including the ability to apply PID control, means the potential applications are numerous and varied.

The editor interface is easy to use – no programming language is involved.

Specification

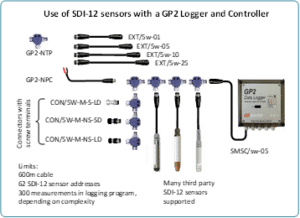

| Input connections | 12 differential (or 24 single-ended) analog inputs configurable as: Voltage, Resistance (12 3-wire or 24 2-wire), Bridge (12), Potentiometer (12) 4 digital inputs as: Counters, (2 fast + 2 slow), Frequency, Digital state 1 Delta-T WET sensor channel Unlimited virtual channels Serial input channel: 62 SDI-12 sensors or a single WET Sensor |

| Control outputs | 2 relay outputs expandable to 6 (1 A) |

| Readings stored | 2.5 Million |

| Recording rate | 1 second to >24 hours |

| Configuration | DeltaLINK |

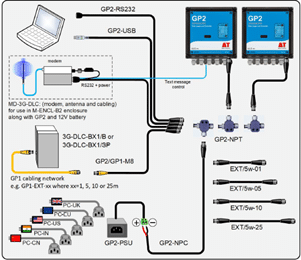

| Communication options | SDI-12, USB, RS232, ethernet or modem |

| Sensor excitation | Calibrated 3 V reference, +5 V and +12 V regulated, or 5 to 10.5 V (battery or external power), user selectable |

| Power | 6 AA alkaline batteries or external power 10-15 V DC |

| Battery life (dependent on usage) | >310K readings, lasting 530 days |

| Enclosure rating | IP65 |

| Temperature range | -20 to +60°C |

| Display | – |

| Size | 225 x 185 x 75 mm |

| Typical applications | Demanding research projects |

| Environmental monitoring | |

| Varied control applications |

| Sensor compatibility (maximum number of sensors that could be connected [1] | |

| WET150 | ✓ (62) |

| ML3 | ✓ (6) with temp / (12) without temp |

| SM150T | ✓(6) with temp / (12) without temp |

| PR2 | ✓(2 PR2/6) (3 PR2/4) |

| PR2 SDI-12 | ✓ (50) PR2/6 ✓ (62) PR2/4 |

| WET Sensor | ✓ (1) |

| EQ3 | ✓ 6 with temp / 12 without temp |

| Temperature | ✓ (12) |

| Tensiometers | ✓ (12) |

| Counters or Events | ✓ (4) 2 fast 2 slow |

| Relay Output | ✓(2) expandable to (6) |

Accessories

Hardware

Main components and software

Mountings and enclosures

- Battery Box – up to 120AH

- DL-MKT Mounting Plate for GP2, GP1 OR DL6 Logger

- WS-CAN – GP2 and DL2e Logger Canopy

- M2-MIN-FSG 2m mast, excluding logger canopy

- M2-FSG 2m mast, excluding logger canopy

- M2-FSG 2m mast for GP2 Logger

- M2 BASE Base socket for M2-FSG, M2-MIN-FSG or S-POLE

- M-ENCL-B2 – Enclosure and 12 V wiring kit for GP2

Installation accessories

Cables and networks

Remote communications

Spares and consumables

Power options

Other

Product Resources

Data Sheets

- GP2 Data Logger and Controller Data Sheet 4 MB

- DeltaLINK-Cloud - online data viewing and sharing service 2 MB

- GP2 Data Logger cabling and network options 1 MB

- WS-GP2 Weather Station Data Sheet 612 KB

- Environmental and Meteorological Sensor Specifications 5 MB

Case Studies

-

Cranfield University - Using the GP2 to improve banana irrigation management in ColombiaFilename: →

-

Research institute uses the GP2 to investigate the effects of protective covering on fruit cultivationFilename: GP2 Data Logger

-

GP2 Data Logger and sensors used by Rothamsted Research for major experimentFilename: GP2 Data Logger

-

Seven brief Delta-T Devices soil moisture measurement case studiesFilename: →

-

BBRO use GP2 Logger & WET150 to tackle drought risk in sugar beetFilename: GP2 Data Logger

Software

Videos

Manuals

- GP2 Data Logger User Manual v 3.2Filename: →

- 3G Modem Gateway User Manual 1.2 2 MBFilename: 3G_Modem_Gateway_User_Manual_v1.2

- M Enclosure for GP2 User Manual 3 MBFilename: m-encl-b2-um-5-0

- WS-GP2 Quick Start Guide v2.4 2 MBFilename: WS-GP2 Quick Start Guide v2.4

FAQs

-

Setting up an M12 cable network to ensure a waterproof and secure connection.

Question

What is the best practice for setting up a M12 cable network to ensure a waterproof and secure connection..

Answer

It applies to:

GP2 for SDI-12 and logger networks.

Celora for SDI-12 networks.

All sensors with M12 connector cables.Examples of SDI-12 network and GP2 logger networks:

DO

When connecting multiple cables and T-piece together, it is essential that any M12 connector is tightened sufficiently:• Ensure internal connector O-ring and opposite sealing face are free from dirt.• Tighten the connector thumbscrews as much as you can by hand or use a torque driver set to 1Nm to be sure. See video:

We recommend the Weidmuller ‚”1900021000″ torque driver:

• This will save lots of painstaking troubleshooting hours if you do have a loose connection and give you piece of mind that all connectors are correctly tightened.

• Untightened connectors can come undone and let water into the cable network which can damage wire cores and cause erroneous readings.

Connect in the office first and then transfer the network to the field. This way, you’re not trying to do it in unpleasant weather and the time pressures are off.

DON’T

Use duct tape. This will hold water against the connector. If tightened correctly, the connector will seal and hold. -

Are there simple protocol commands to communicate with the Delta-T Devices Data loggers, so I can set up my own test software to communicate with them?

Question

Are there simple protocol commands to communicate with the Delta-T Devices Data loggers, so I can set up my own test software to communicate with them?

Answer

GP1, GP2 and DL6

The GP1/GP2 and DL6 loggers have a binary communications protocol, so it isn’t possible to use an ASCII terminal to communicate with them. We don’t publish the protocol because it’s highly optimized and complex, and it’s not practical for us to support development of custom implementations. Instead we provide a software development kit (SDK) for developing applications in Visual Studio, and a command line program for use in batch files for automating data retrieval.

- Using the development toolkit:

Instructions:

SDK instructions

Software can be found here:

link to software - Using a command line retrieval file to automatically retrieve a data file:

command line document link

DL2e

The DL2e does have a protocol for RS232 commands and the programmer’s guide can be found here:

DL2e programmer's guide - Using the development toolkit:

-

How do I set up my USB to RS232 convertor? – Photo Guide

Question

How do I set up my USB to RS232 convertor? - Photo Guide

Answer

- These convertors usually come with a website link to visit and download the drivers. Please make sure you download the drivers. Then follow all the on-screen instructions correctly.

- If you have purchased the device from Delta-T, you can download the drivers from here: https://www.dropbox.com/s/2pu0ll8b26y8qkm/CDM212364_Setup.exe?dl=0 or here: https://ftdichip.com/drivers/vcp-drivers/

- Once the drivers have been installed correctly, plug the USB convertor into a USB port on your PC.

- The computer will then assign the convertor a COM port. You will need to check which com port has been assigned via the computer’s “device manager”:

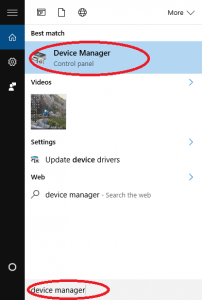

Windows 10

Use the search tool in the bottom task bar to search for ‘device manager’:

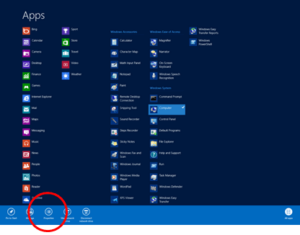

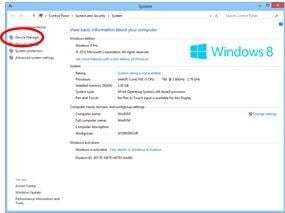

Windows 8

Right click on Desktop background and select ‘All Apps’Right click on control panel and select ‘properties’:

Click on Device Manager:

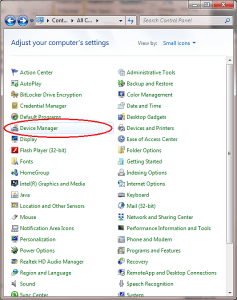

Windows 7

Click on Start, Control Panel, Device Manager:

XP

Click on Start, Control Panel, System:

Under the ‘Hardware’ tab, click on ‘Device Manager’:

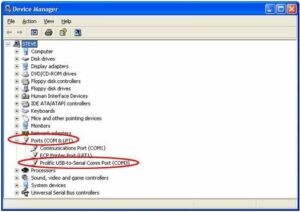

- Once in the device manager, expand the “ports” option. The example below shows a P.C which has the USB to serial converter installed (COM3):

- Please make sure that you use this same COM port number in the device software e.g. HH2read, SunRead, LS2win, DeltaLINK, AP4 retrieve.

- You will probably have to re-boot the P.C once the drivers have been installed.

- Also, please remember to use the original RS232 cable, that was supplied with your device, in series with the RS232 to USB converter.

Multiple USB convertor Installations check

If you have more than one USB to RS232 convertor installed, you can check which COM port has been assigned to the one you want to use, by doing the following:

- Unplug the USB convertor

- Open Device Manager > Ports (COM & LPT)

- Plug in the USB connector and observe which COM port is added to the list.

Technical Notes

-

User guide to Penman Monteith Evapotranspiration in the GP2 Data logger 876 KBFilename: User_guide_to _Penman Monteith_ Evapotranspiration_in_the GP2_Data_logger

-

A method of calibration and variance analysis with respect to the Penman-Monteith equation for the Turc, Hargreaves and Abtew potential evapotranspiration models 1 MB

The full ASCE/FAO-56 Penman-Monteith evapotranspiration (PM-ET) equation and crop coefficients are often employed for irrigation scheduling of open-field crops. This paper focuses on the Turc, Hargreaves and Abtew models which employ daily averages of: solar radiation, air temperature and relative humid to determine daily ET.

Filename: Calibration and variance analysis with respect to Penman-Monteith equation for potential evapotranspiration models 5.8.19

Advanced features of the new GP2 Data Logger and Controller

- Powerful, yet highly accessible Script Editor

- Virtual Channels

- Unique Simulator function

- Smart irrigation and fertigation

- PID control

- Model implementation, simulation and evaluation

- Evapotranspiration calculation and analysis

Customised control (simple or advanced)

Control conditions for experiments and applications can range from simple thresholding to sophisticated calculations using the Script Editor. Control parameters (e.g. target soil moisture level) can be adjusted without interrupting data logging.

Script Editor

The GP2 is a flexible and powerful research and control instrument – enabling model implementation, simulation and evaluation. The new Script Editor is easy to use, yet allows the creation of complex functions such as disease prediction, degree days, dew point, wind chill factor, PID control, and evapotranspiration calculation and analysis.

- Script Editor creates sequences of operations to implement models

- Advanced control and recording capabilities

- Easy user interface: no typing out of commands; no programming language

- Implement simple or complex conditions, algebraic expressions and record result values

- Create and manipulate variables e.g. for disease risk factor

This powerful software feature creates step by step operations to control simple or complex processes or recording requirements. The editor interface is easy to use – no programming language is involved. It can also implement models, useful in areas such as disease prediction or multi-zone irrigation. This degree of sophistication, including the ability to apply PID control, means the potential applications are numerous and varied.

Virtual channels

Calculations based on the measurements from several input channels can be recorded and displayed as additional “virtual channels”.

Simulator

- Test and optimise logging programs using the built-in Simulator.

- Simulate how the program responds to changes in weather data, irrigation systems and soil moisture movement etc.

This unique software feature allows logging programs to be tested before real-world activation. For applications involving weather data, irrigation or soil moisture recording, the environmental variables can be changed to test how the program responds. Years of logging time can be simulated in just a few minutes.

Typical examples of advanced control and modelling

PID Control – The GP2 is a powerful research tool for experimental research. The powerful new Script Editorfunction gives the user an accessible way to create sophisticated mathematical functions and models that can be applied in real-time to the measurement data collected by the GP2. In experimental work detailed here we have created an enhanced PID controller within the DeltaLINK 3.0 Script Editor – enabling the GP2 to deliver precision irrigation control for a Poinsettia plant. The data collected shows precise control of soil moisture levels and the PID controller responding appropriately to the diurnal cycle. The experimental system also includes water flow and radiation sensors. The GP2 collects data from these sensors and calculates daily totals enabling the relationship between solar radiation and water use to be investigated.

Download GP2 PID scientific poster here.

Explanation of PID Control

Evapotranspiration calculation and analysis In this example, the GP2’s Script Editor & Simulator features were used for a comparison of four empirical potential evapotranspiration equations (PET). The Script Editor was used to implement mathematical models (Xu & Singh 2001) that calculated daily average values for air temperature, relative humidity, and solar radiation. These values were then used with empirical models to estimate PET. The results indicate that the solar radiation based models are well grouped and follow a similar trend, whereas the temperature based model (McCloud) appears to overestimate PET.

The empirical PET models described in the poster can be installed into a standard GP2, and with the appropriate sensors, used to calculate real-time estimates of PET. If comparison pan evaporation or lysimeter data is available then the model coefficients can be adjusted on the GP2 to optimise the model for local conditions as outlined by Xu & Singh (2001).